I invite you to read my quick buttonhole tips below and then CLICK HERE to watch It's Sew Easy Episode 810.

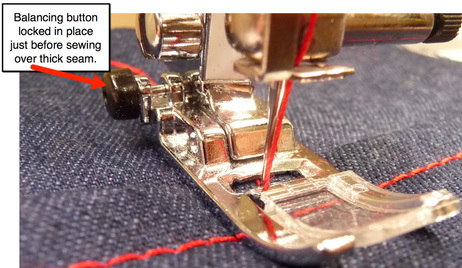

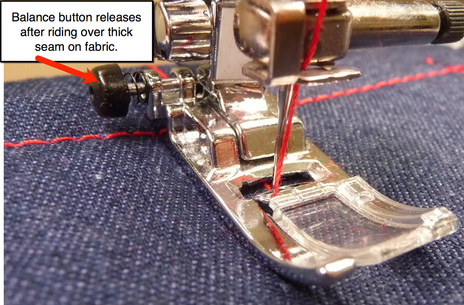

- Always, always, always, make a test sample using the exact same conditions you will have for your final fashion buttonholes. Do yourself a favor and work up a sample piece with identical elements to practice on. If this means you’ll encounter the bulk of a seam then you’ll want to make a sample that mimics that same situation. Remember to properly grade seam allowances and then thoroughly press to eliminate as much bulk as possible.

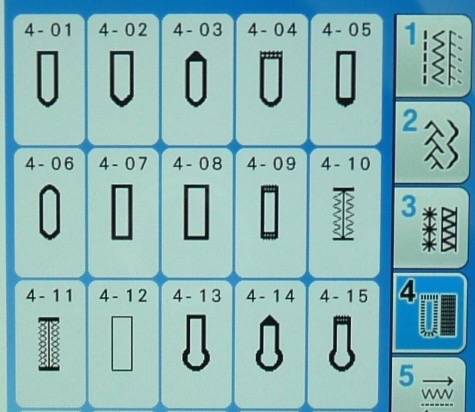

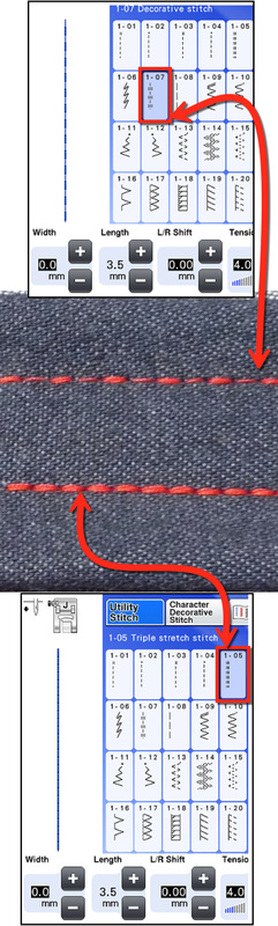

- Try out different buttonhole styles and settings. Depending on your machine you may have many to choose from. I suggest making a sample of each buttonhole available on your machine to use for future reference. Generally, I like round-ended buttonholes for blouses, and keyhole style buttonholes for shank style buttons. But those are just traditional choices, feel free to break the rules. If the final button hole looks good with your button on your garment that’s all that counts!

- Plan to stitch your buttonholes when you are at your best, mentally and physically. Strive for uninterrupted quiet time so you can thoroughly concentrate. Once I made a garment that took many hours of embroidery to complete. When it came time to sew the buttonholes I got up very early (early for me anyway) and stitched them in the quiet of the day. I think even the cat was still asleep that morning! I know it’s a little tough to see the results in the pictures below but trust me this outfit has been photographed professionally and used in advertising materials. These carefully crafted buttonholes are worthy of the attention. This was and continues to be one of my favorite embroidered outfits.

- I can’t say enough about the virtues of a One-Step buttonhole attachment like the one you see below. It will even accommodate many shank style and novelty buttons. This is a common accessory for many machines. It's worth upgrading for if you intend to sew many buttonholes and your current machine is without this modern day feature. Visit your local sewing machine dealer for a demonstration of this little beauty. It can be found on many machines. You're sure to find one that fits your budget.

- Try using machine embroidery thread in place of ordinary sewing thread for you next buttonhole. This type of thread comes in so many colors and it's thin, smooth and has a beautiful sheen. I think this type of thread imitates silk and that is what a tailor would use to make a hand worked buttonhole. I use this type of thread exclusively for every buttonhole I make on a garment.

- Select a needle that compliments your fabric. In fact, this may be the best time to change the needle and start fresh. If you have used the same needle throughout the construction of the agreement it is probably due for replacement. Make a note when you remove the needle telling yourself that it is new and you'll be set for the next garment you make. One more note on needles, my philosophy is "when in doubt - throw it out!"

- Most items with buttonholes will have interfacing sandwiched in the layers. Consider adding a removable stabilizer to beef up the fabric temporarily while you stitch the buttonhole.

- If your fabric is compatible with a seam sealant such as Fray Check, use it to seal the buttonholes before you cut them open. Let dry. Then, seal again if necessary after cutting the buttonhole. Be very careful when cutting; use a sharp seam ripper or a special buttonhole cutting tool.

RSS Feed

RSS Feed