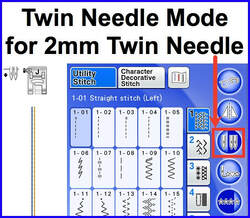

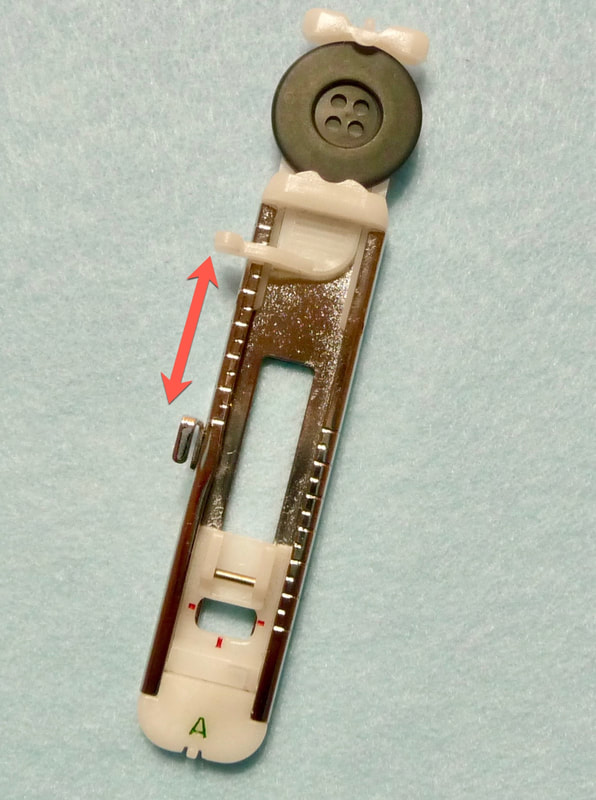

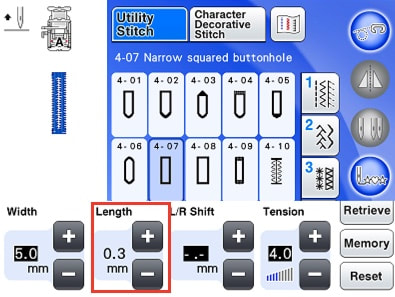

When zigzag or decorative stitches are selected, you will need to calculate the maximum stitch width allowable. This formula will be figured in millimeters, as that is how double needles are sized. First, determine your machine’s maximum stitch width. This is the largest size zigzag it will produce. Subtract the double needle size between points. The resulting figure is the maximum decorative stitch width you may use without risking needle breakage. Always hand walk the needle as a precautionary measure before stitching to insure that your needle will not hit the side of the throat plate. For straight stitching, be sure to use the center needle position on your machine. When using a straight stitch, the maximum stitch width on your machine determines the maximum size double needle your machine will take.

Threading the Machine for Twin Needle Sewing

You will need two spools of thread with each one placed on its own spool pin. Bobbins can be wound and used in place of a second spool of thread. If you do use a bobbin, place a spool of thread on top of it just to keep it from “jumping” during stitching. Follow these tips for proper threading:

1) Place the first, or left, spool so that the thread reels off from behind the spool. Place the second spool with the thread unwinding from the front of the spool.

2) Both spools should be threaded in one operation, however, they will not share all the thread guides.

3) If there is just one tension disc, both threads will share the disc. If there are two, at the point of the tension discs you will separate the threads, placing one thread on each side of the center tension disc.

4) If there are two thread guides just above the needle, separate the threads there also. In the case of one thread guide, place one thread inside the guide and leave one outside the guide.

5) Separate the threads when you reach the needles, making sure threads are not twisted. Depending on the stitch desired, the top tension may be adjusted up or down. Bobbin tension will remain normal.

RSS Feed

RSS Feed